Defects Per Million Opportunities (DPMO)

Defects per Million Opportunities factors in the total opportunities for defect occurrence existing in a process. DPMO is considered long-term measurement of a process and this can be directly converted into a long-term z-statistic (sigma value)

Given:

D: # of defects

O: # of opportunities for a defect

U: # of units

TOP: Total number of opportunities = U * O

Formula:

DPMO = DPO * 1,000,000

DPO = Defects per Opportunity

DPU = Defects per Unit

See the links or the example below to help understand the differences.

NOTE:

DPMO is NOT the same as PPM (parts per million) since it is possible that each unit (part) being appraised may be found to have multiple defects of the same type or may have multiple types of defects. A part is defective if it has one or more defects. The number of defectives can never exceed the number of defects.

IF each part only has one characteristic that can be a defect, then DPMO and PPM will be the same.

You could have 1,000,000 defects on one part and the DPMO could be 1,000,000 and the PPM is 1.0 if that part is the only part out of the million that has any defects (in other words the other 999,999 parts have 0 defects). This is an exaggeration to try and illustrate the difference between DPMO and PPM.

Also keep in mind that it's possible that each widget being measured (or assessed) has a different amount of potential defects. So theoretically you could have just a few widgets (very complex widgets) that have thousands of opportunities for defects or a lot of simple widgets that only have a few total opportunities for defects.

PPM represents the number of defective parts (units) per 1 million units

DPMO is the number of defects per 1 million opportunities of defects

DPMO Example

Examine the table shown below:

Nail #1 has two types of defects. Therefore it is ONE defective nail that contains TWO defects.

SUMMARY OF TABLE

D = 19 total defects

O = 5 opportunities (categories of defect types)

U = 10 nails

TOP = U * O = 50 total opportunities for defects

DPU = D / U = 19/10 = 1.9 defects per unit

DPO = D / TOP = 19/50 = 0.38

DPMO = 380,000

Out of a million opportunities, the long-term performance of the process would create 380,000 defects.

Notice that only Nail #3 and Nail #9 had zero defects. Therefore 8 out of 10 nails had at least one defect. That represents a PPM of 800,000.

Want to convert a DPMO of 380,000 to a z-score? Read below or click here to learn more about z-scores.

Using Excel to calculate Sigma and DPMO

There are a couple

commonly used Microsoft Excel functions that converts Defects per

Million Opportunities (DPMO) to a process sigma (z-score) and vice

versa.

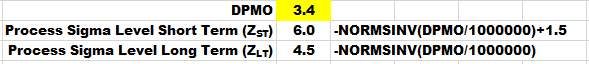

To convert from DPMO to process sigma:

- Process Sigma (ST) = -NORMSINV(DPMO/1,000,000)+1.5

- Process Sigma (LT) = -NORMSINV(DPMO/1,000,000)

To convert from process sigma to DPMO:

- DPMO = 1000000*(1-(NORMSDIST*(process sigma-1.5))

To convert DPMO to % Defective

- DPMO / 1000000*100 = % Defective

NOTE:

A

Six Sigma quality process refers to the process short-term performance

or how it is performing currently when there are 3.4 DPMO. Over the long

term, this six sigma process is estimated to shift -1.5 sigma (lower)

and will perform at a 4.5 sigma level, which produces 1,350 DPMO.

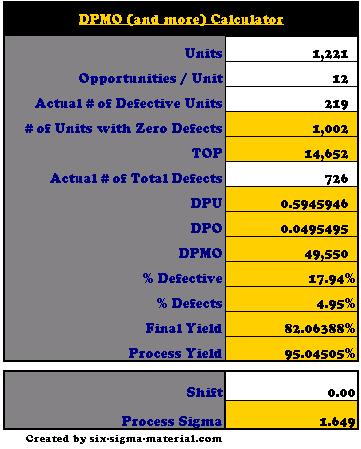

DPMO Calculator (Six Sigma Calculator)

Enter your values in the white cells and everything else is calculated. Notes are in the actual template that offer more guidance and information on each row.

This calculator can give you a ZST (if you input a shift of +1.5) or ZLT score (if the shift is 0). This is shown at the bottom as the 'Process Sigma' value.

DPMO (and more) Calculator available for your Six Sigma project

Return to the Six-Sigma-Material Home Page

Recent Articles

-

Process Capability Indices

Oct 18, 21 09:32 AM

Determing the process capability indices, Pp, Ppk, Cp, Cpk, Cpm -

Six Sigma Calculator, Statistics Tables, and Six Sigma Templates

Sep 14, 21 09:19 AM

Six Sigma Calculators, Statistics Tables, and Six Sigma Templates to make your job easier as a Six Sigma Project Manager -

Six Sigma Templates, Statistics Tables, and Six Sigma Calculators

Aug 16, 21 01:25 PM

Six Sigma Templates, Tables, and Calculators. MTBF, MTTR, A3, EOQ, 5S, 5 WHY, DPMO, FMEA, SIPOC, RTY, DMAIC Contract, OEE, Value Stream Map, Pugh Matrix

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more