CONTROL

The final phase of a DMAIC Project!

The CONTROL phase is the conclusion of the team's journey. The GB/BB is responsible for a solid hand-off to the Process Owner to maintain the gains.

The final capability is determined and the closing performance and all related changes are documented on the closing contract. This phase is not as statistically intensive as the MEASURE, ANALYZE, and IMPROVE phases.

Rewarding the team and stakeholders is important because they not only deserve it but to leave on a final positive note and grow credibility for the GB/BB and the company's Six Sigma program.

There can not be enough emphasis placed on the importance of devoting the same high level of energy and commitment throughout this phase. Complacency and anxiety can set in for the sake of bringing closure receiving credit for executing a project.

This can result in the process reverting to the former performance levels and loss of some or all of the gains. In addition, the Six Sigma program and the GB/BB lose credibility.

One of the most common complaints of a Six Sigma program is that is a "flavor of the month" or "common sense stuff". Rigorous follow-up and corrective action with comprehensive documentation can increase the likelihood that the gains are sustained.

The number one killer for your reputation as a GB/BB and the overall company's program is when a process reverts back to the original performance...do not allow that to happen.

The GB/BB should also make recommendations to upper management or a MBB for future project recommendations to further improve process performance. These can lead to new Six Sigma projects or Kaizen Events. Present some interesting findings and improvements that stemmed from the findings.

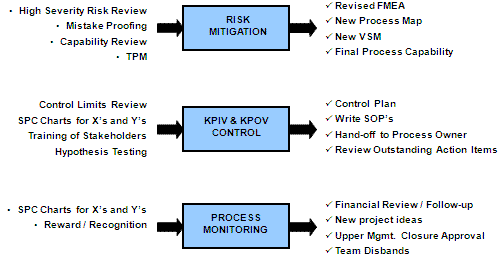

Below are a list of tools commonly used in this phase.

SPC Charts

Assessing Final Process Capability

Process Yield Metrics

FY - Final Yield

TPY - Throughput Yield

RTY - Rolled Throughput Yield

NY - Normalized Yield

Other Tools

Revised FMEA

Mistake Proofing

Control Plan

Testing Methods (Destructive and Nondestructive)

Verify Financial Savings

and finally.....close out the Project Contract!

Recalculating Control Limits

Once the improvements are complete it

may be warranted to calculate new process control limits and make these

limits the triggers for corrective and preventive action.

If the

three questions below can be answered YES then recalculate the control

limits of the process and use them on the SPC charts and document them

on the Control Plan for future monitoring.

- Is the data statistically different from BEFORE and AFTER?

- Are the reasons for the change understood and favorable?

- Is the AFTER behavior expected to represent future performance in the long term?

If

you can not answer YES to all of the above criteria then the Process

Owner should have information in the Control Plan that identifies corrective

action and ideas for the special causes (assignable causes). The

process is probably not mature, or in enough control, to use recalculated

control limits.

Process control should be done before assessing final process capability.

|

Before and After Capability Roadmap This download is available to members |

Templates, Tables, and Calculators

Six Sigma Certification programs

Subscribe to access entire site

Search Six Sigma related job postings

Return to the Six-Sigma-Material Home Page

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more