LEAN Manufacturing

Lean Manufacturing focuses on LEAD TIME (CYCLE TIME) REDUCTION.

The objective is converting raw material to cash as quick as possible, optimize the cash conversion cycle.

Lean tools help to expose problems and purposely find ways to make problems evident. It teaches people how to "see" what isn't obviously visible. You will learn to "see" what you can't see....known as the "hidden factory". "Bad news doesn't get better with time"

It is accomplished by the elimination and reduction of waste. The tools reveal areas of opportunity and guide the prioritization of improvements.

Lean Manufacturing begins by studying the FLOW in three areas:

- MATERIAL

- PEOPLE

- INFORMATION

Before getting ahead of ourselves, like any other project, all the efforts must equate to value, or at least not reduce the value, to the customer. The customer can be an end-user and the company. There are generally five principles that pertain to Lean Manufacturing and these are not the D-M-A-I-C for Six Sigma. However, these five principles are continuous, and are continuously monitored and refined with a pursuit of perfection.

The 5 Principles of Lean Manufacturing:

- Determine the Voice of the Customer and Value proposition. Usually a reduction in lead time not only increases working capital for your company but makes your process quicker, more responsive, and flexible. This is value.

- Value Stream Mapping. This tool is also an integral part of most Six Sigma projects that creates a Current and Future state to "Lean" out a value stream. It's a powerful tool through illustration and numbers that quickly identify opportunities to reduce lead time and the cash conversion cycle. The focus is on operational tactics rather than things like payment terms, refinancing debt, and finance functions (although these are important too).

- Remove constraints and enable Flow. Perform a constraint analysis by studying Takt Time and Loading charts. These can create a wholesome picture of the value stream and where to focus improvements.

- Implement Pull. The use of Workcells, Kanban cards, remove Waste, and Visual Management are some tools used to implement a Pull system.

- Monitor, refine, and restart the process of improving to the next level (PDCA).

In this era of globalization the ability to quickly adapt and continuously improve is much more than a technical challenge. The rate of change in the world is increasing. Strategic and tactical issues will become more complex and those that change at the fastest, with accuracy, will have the competitive advantage.

The Japanese instructors demonstrated this in their NUMMI plant, a joint venture between Toyota and General Motors in Freemont, California. When adequate attention and training was devoted to the cultural transformation along with the other Lean tools, American workers were able to produce Japanese cars just as efficiently with the same level of quality at their Japanese counterparts.

Difference between Lean & Six Sigma

The primary difference between Six Sigma and Lean Manufacturing is:

- Six Sigma uses statistics to identify and reduce variation in processes to satisfy the customer*. The first priority is control which is precision and to have that precise output on a target (which is accuracy).

- Lean Manufacturing focuses on finding and eliminating waste in processes to satisfy the customer*. This increase the velocity of process flow and thus allows a reduction in inventory (as long as it is a stable process...hence the purpose of Six Sigma) and possibly get cash sooner.

*remember the customer is not only the end-user but may also be your company. These concepts are often combined within organizational structures and called "Lean Six Sigma".

The Theory of Constraints is another method that is often combined in these two programs. This focuses on evaluating constraints operations and processes and using tools such as Takt Time and Line Balancing to optimize throughput.

Six Sigma has a higher emphasis on product quality than Lean Manufacturing, where-as Lean Manufacturing has a higher emphasis on speed and cycle time reduction than Six Sigma. Both cycle time and quality are important, but each program focuses on them to a different extent.

Walk the Talk

Lean Manufacturing is more than “just-in-time”, shortening up the cash conversion cycle, and SPC, but just as much as cultural and management mindset. Similar to a Six Sigma program, the technical abilities of the program and those trained to guide it are only part of the system.

The difference is finding leaders and project managers that can drive transformation and cultivate change on an ongoing basis - SUSTAIN. The total Lean system must have both components to succeed.

Japanese workers are groomed from a basic level of having no knowledge of the specifics for their job. The amount of training hours per workers greatly exceeds the hours dedicated to most of the workers in other parts of the world. But the reward is more significant later when the culture quickly spreads, errors are limited, variation is limited, and synergies are working.

It is similar to a DFSS (or DMADV) Six Sigma project where a majority of time, energy, and money are dedicated up front to enable a product to be at a "perfect quality level" at introduction. From then on it will require fewer resources delivering consistent stability and profitability for the long run. Haste makes waste, but when a solution is found it is implemented quickly and across the entire system.

Focus on the ultimate state....that every person, every square inch of floor space, every cubic inch of volume space in your plant, hospital, or office, at every second of the year is producing VALUE for your customer.

Anything that is not, is waste or a support function or operation (such as staging, maintenance, tooling, quality control, offices, storage). Look around and see how the vertical space can be used better, layouts to use the floor space to create money.

Automation is not always the best choice to improve a value stream. Many companies must change quickly to keep up with the globalization and dynamics of the competition. Automation is expensive and fixed. Often, you can't train it (program) as easily and quickly as humans. There are complications and unplanned downtime when it fails.

Jidoka is a term that emphasizes partial automation since this option may cost significantly less than complete automation. A bottleneck operation may require such an investment but a compromise using some form of partial automation with limited human interaction could offer a quicker and much more affordable option.

Jidoka provides insight to design these options with an emphasis on automatic stops upon a defect being detected.

All these pros and cons need to be considered before resorting to automation to reduce lead time or poka-yoke. Each application is unique, in some cases automation is the clear choice and other times it is better to utilize the power of people and empower them to be responsible for the value they add to the product or process.

Employee Ownership

The importance of employee participation and retention is paramount to a successful foundation and sustaining a LEAN culture. Although restructuring during a slow time may not be avoidable, it is the last resort when trying to transform into a Lean Manufacturing culture.

LEAN MANUFACTURING focuses on elements that seem elementary but specific tools and training can lead to valuable gains. Furthermore, the tools guide the team to reveal DFSS and waste removal opportunities AND improve existing value-added processes (i.e. speeding up an existing running machine with better maintenance program).

Lean tools can also be applied to transactional process as well as the DFSS and DMAIC tools.

Value stream mapping is a key component of Lean Manufacturing. Most often a product value stream will consist of 95% or more non value-added time.

That means that most value streams begin with <5% of the total time devoted to adding value or creating a feature that the customer is willing to pay for.

In many cases, there is business (or regulatory) time that complicates the map. Many companies must perform record keeping, audits, data entry, and maintain environmental, health, and safety compliance that take time in the value stream. While it is mandatory, it is still non-value added and should be challenged and streamlined to lean out within reason.

Many of the tools are taught to an entire workforce to develop a foundation of LEAN thinking in day to day operations. Some of the tools used are:

Gantt Chart

OEE - Overall Equipment Effectiveness

TQM - Total Quality Management

Designing Workcells / Cellular Flow

Total Productive Maintenance (TPM)

SMED: Single Minute Exchange of Dies

Inventory Control

Value Stream Mapping

Lean Manufacturing questionnaire

Many people associate being "Lean" with having a very efficient workforce, with many people pitching in in various ways to do whatever is necessary to get the job done...in other words, wearing multiple hats.... and usually firefighting.

However, Lean Manufacturing encompasses a different set of principles. While it also may result in workforce that can do more with less, the loading is constantly adjusted and refined to meet the Takt Time.

Members will have access to this Lean Manufacturing questionnaire that serves as a guide to help understand whether a workplace has the basic principles of Lean Manufacturing.

Click here to learn about subscription options.

Lean Six Sigma

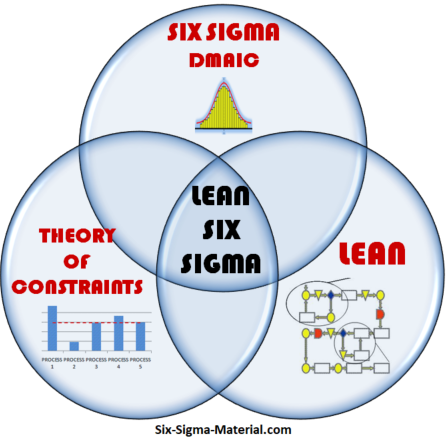

Many organizations are combining the principles of Lean Manufacturing, Theory of Constraints, and Six Sigma into one program and labeling it Lean Six Sigma.

At a high level the three methodologies are summarized below.

- Lean Manufacturing reduces waste through process map improvements

- Theory of Constraints concentrates on relieving bottleneck operations

- Six Sigma reduces and controls process variation with the help of statistics

All three of them have a collective goal to improve the process performance towards a target (improve the mean), improve customer satisfaction and more profitable.

You may fall short of satisfying the customer if using anything short of all three. Any of the three are beneficial but may not be enough alone to get the best results.

A successful project will have controllable inputs that provide consistent and accurate output. This type of result requires the collective use of all three methodologies.

Link to the newest Six Sigma Materials

Test your Six Sigma knowledge with these certification problems (subscribers only)

Return to the Six-Sigma-Material Home Page

Recent Articles

-

Process Capability Indices

Oct 18, 21 09:32 AM

Determing the process capability indices, Pp, Ppk, Cp, Cpk, Cpm -

Six Sigma Calculator, Statistics Tables, and Six Sigma Templates

Sep 14, 21 09:19 AM

Six Sigma Calculators, Statistics Tables, and Six Sigma Templates to make your job easier as a Six Sigma Project Manager -

Six Sigma Templates, Statistics Tables, and Six Sigma Calculators

Aug 16, 21 01:25 PM

Six Sigma Templates, Tables, and Calculators. MTBF, MTTR, A3, EOQ, 5S, 5 WHY, DPMO, FMEA, SIPOC, RTY, DMAIC Contract, OEE, Value Stream Map, Pugh Matrix

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more