MEASURE

The 2nd phase of a DMAIC Project.

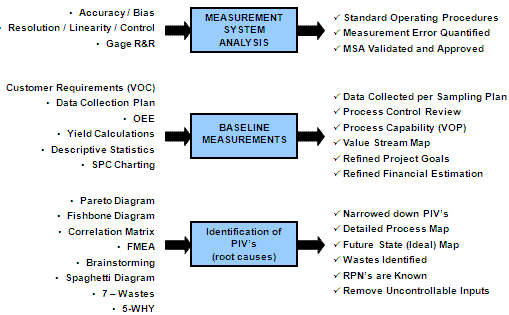

The MEASURE phase involves more numerical studies and data analysis than the DEFINE phase. This phase focuses on measurement system validation and gathering root causes.

The Voice of the Process (VOP) has variation from both the measurement system and the process and all its families (sources) of variation. The MSA will quantify the amount of variation found in the data that is induced from the measurement system.

The next phase, ANALYZE, uses statistical tests to quantify the variation due to the inputs only (separate from the MSA variation).

Many projects stall at this phase; conducting a MSA can be an exhaustive effort. Prepare to buckle down and test your knowledge of basic statistics. Many measurement systems need work or can be improved with simple action, others will require much more and can become a project all by itself.

Refine the Contract/Charter:

In this phase, the problem statement and project contract are commonly refined as a result of establishing an accurate baseline for the metrics being targeted. Without being able to measure, it is impossible to quantify change....furthermore, what gets measured usually gets improved.

Learn the Software:

This phase will most likely introduce statistical software. There's a big advantage to those that are more fluent with the software. Put the time into familiarizing yourself with the statistical software package prior to starting a project. It's highly encouraged to use the HELP menu to your advantage and experiment with mock data.

Data Collection:

Systems with archives of data often have flaws, or the data only occurs infrequently. Data collection takes time from operators and management and can be viewed as a burden.

Finding the balance to get as much information as possible that is proven reliable while not consuming excessive resources is key to success in this phase.

This data collection will often encounter resistance and can lead to the temptation of taking the easier routes, rounding off numbers, or otherwise skewing and creating inaccuracies. Education, awareness, rule setting, and up front discussion with all stakeholders (not just team members) is necessary to get the most cooperation and validity in data collection.

Without taking away from the importance, often times teams cruise through the DEFINE phase then find out that data collection and analysis are very time consuming and challenging.

Shown below are some of the commonly used tools within the MEASURE phase:

Maps

Process Maps

Value Stream Mapping

Data Collection

Data Collection

Data Sampling - Population vs. Sample

Data Classification

SPC

Statistical Process Control (SPC) Charts

MSA

MSA - Measurement System Analysis

Testing Methods (Destructive and Nondestructive)

Gathering Root Causes

Root Cause Analysis

5-WHY

Fishbone Diagram / Ishakawa Diagram / Cause and Effect Diagram

Correlation Matrix

FMEA - Failure Mode Effects and Analysis

A3 Problem Solving Tool

Project Metrics

Establishing a Baseline Measurement

DPU - Defects per Unit

DPO - Defects per Opportunity

DPMO - Defects per Million Opportunities

Z-score - sigma scores (standard deviations from the mean)

Process Yield Metrics

FY - Final Yield

TPY - Throughput Yield

RTY - Rolled Throughput Yield

NY - Normalized Yield

Other Topics

Box Plot (also variable width and notched)

Stem and Leaf Plot

Overall Equipment Effectiveness (OEE)

Proceed to the 3rd phase of a DMAIC project: ANALYZE

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more