Scatter Diagram

Scatter Diagrams (or Plots) are used to visually represent data for further analysis in correlation or regression. The diagram shows a pair of numerical data, one for each axis (horizontal and vertical with are x-y respectively). It shows the relationship between 2 variables.

They explore associations between two variables and the "x" variable (input) is varied systematically and the "y" (output) is measured once the input changes. The intention is to visually examine trends or patterns of the input (x) onto the response in the experiment.

The chart below would indicate a weak negative linear correlation. From here the Coefficient of Correlation can be determined as well as best fit line to describe the behavior of the data.

A possible negative correlation but not overly convincing

A possible negative correlation but not overly convincingThere are no assumptions of normality or sequence to use a Scatter Plot. Sequential plotting is required for a Time-Series plot (and for SPC). In other words, the data for Scatter Plots does not have to be in sequence or chronological order but this is required for SPC and Time-Series charts.

It is most useful when there is a lot of data in table and very difficult to tell if there is any type, and to what degree, of correlation.

As association of variables does not always imply cause. There could be other lurking variables affecting the measured "y" response.

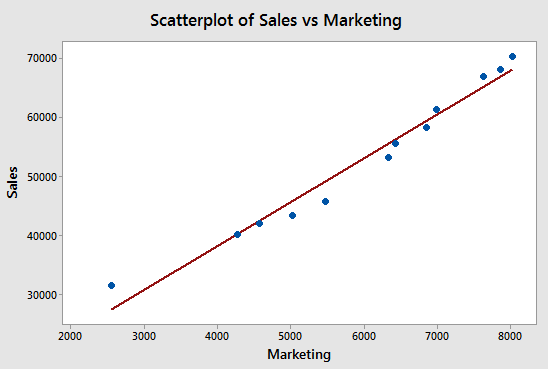

A scatter plot of the blue dots shown below makes it very obvious that there is strong positive linear correlation but it does not provide any value other than a visual indication.

A Scatter diagram itself is limited in its use but is rather a starting point for further analysis of correlation and regression.

This is another one of the many visual tools (such as a Box Plot and Pareto Chart) that a Six Sigma project manager can use to help break down data into more meaningful terms.

Line charts are similar to Scatter Plots but contain lines connecting the data.

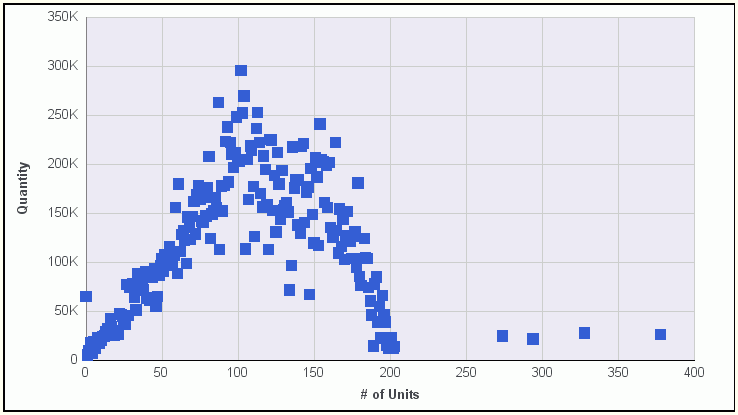

The chart above is an example of the value of the plot. Simply looking at a set of x-y data on a sheet would be a challenge to see this relationship. There appears to be a strong non-linear relationship with a few outliers within the range of 0-200 units.

Those outliers are concerning. There are only a few of them so it would be worthwhile understanding what happened in each case.

Another Example of Scatter Plot

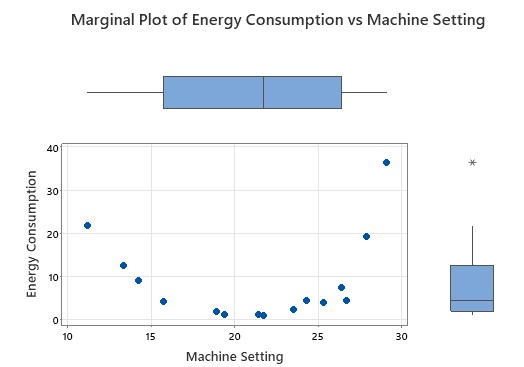

Shown below is called a Marginal Plot (fancy Scatter) a (X variable - the input) which is the Machine Setting and how it affects the Energy Usage (Y variable - the output).

Youi can see the Box Plot of each the X and Y variable too. There are two valuable visual tools on one chart. A lot of quick insight can be seen with this plot.

You can quickly see the relationship is not linear. Two questions arise

1) What is the formula that best fits the data and is it statistically useful?

Knowing the formula that has a strong correlation to the data is very helpful to model other scenarios and find the machine setting that uses the least amount of energy.

Minitab has options to select Linear, Cubic, or Quadrative fit lines, predictive and confidence intervals and the correlation coefficient. That is covered in the Regression module

2) What is the optimal setting to use the lowest amount of energy? A quick observation of the plot shows it will be about 20. That is not so easy to see when you're looking at just the data in a table.

There is one outlier that should be investigated in case it is a faulty data point but it probably won't change the formula too much (depending on how precise you need the machine setting answer to be).

7 Basic Quality Tools

A Scatter Plot is considered 1 of 7 Basic Quality Tools for process improvement. The others are:

- Fishbone Diagram (Cause-Effect Diagram or Ishikawa Diagram)

- Check Sheet

- Control Chart

- Histogram

- Pareto Chart

- and Stratification

If you're considering a Six Sigma Certification exam or a PMP certification, memorize and understand the purpose of these 7 tools.

Templates, Tables, and Calculators

Practice certification problems

Recent Articles

-

Process Capability Indices

Oct 18, 21 09:32 AM

Determing the process capability indices, Pp, Ppk, Cp, Cpk, Cpm -

Six Sigma Calculator, Statistics Tables, and Six Sigma Templates

Sep 14, 21 09:19 AM

Six Sigma Calculators, Statistics Tables, and Six Sigma Templates to make your job easier as a Six Sigma Project Manager -

Six Sigma Templates, Statistics Tables, and Six Sigma Calculators

Aug 16, 21 01:25 PM

Six Sigma Templates, Tables, and Calculators. MTBF, MTTR, A3, EOQ, 5S, 5 WHY, DPMO, FMEA, SIPOC, RTY, DMAIC Contract, OEE, Value Stream Map, Pugh Matrix

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Control Charts

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

Normality

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more