Mistake Proofing (Poka-yoke)

Shigeo Shingo is credited with this concept of mistake proofing. This involves some form of mechanism that helps avoid (yokeru) mistakes (poka).

Mistake Proofing is about adding techniques to prevent defects and detect defects as soon as

possible, if one does occur.

Poka-Yoke is the Japanese term often used as a synonymous term but its meaning is to eliminate product defects by preventing human errors (that are unintentional). The concept was first put to widespread use by Shigeo Shingo within the Toyota Production System (TPS).

When an error can not practically be 100% prevented or detected, then the next best option is to try to reduce the severity of the error and defect.

Objective:

PREVENT a defect from occurring and when this is not possible, DETECT the defect every time one occurs. There are various levels, effort, and costs of error proofing.

The team needs to identify the optimal states and examine feasibility of implementation in the new product or process KPIV's.

The goal is in this priority:

- To prevent the errors that lead to the defects

- To detect defects (not all errors can be 100% preventable)

- To reduce the severity of the defect

If practical and necessary, try to implement all three or a combination of the three options.

Sometimes technology isn’t available to prevent and/or detect errors so the next best solution is to reduce the severity of the defect.

Tools such as the 5-WHY are used to get to root causes of the errors. When thinking about mistake-proofing it is crucial to get to the sources and root causes.

Inspections

Inspections:

- Successive – device/person at the next process checks and provides feedback

- Self-Inspection – device/person inspects own work

- Source – person/device inspects operating conditions before work is performed

(The ultimate state is designing errors out of the process making them impossible to occur)

- Successive inspection is a DETECTION inspection which is reactive and provides information back to the source of the error.

- Self inspection is a DETECTION inspection in which the operator or device checks the work at the process for a quicker feedback loop to the source of the error. This is more desirable than successive inspection.

- Source inspection is the most desirable inspection since the other two occur later in the process resulting more lost time and costs. The error is found after it has occurred. This is a PREVENTION inspection.

Two Varieties

There are two variations of mistake proofing

Inspection itself is not considered a viable technique of mistake proofing. The technique or mechanism that prevents or detects errors or deviations is mistake proofing.

Three Types

Shigeo Shingo coined three types of poka-yokes:

- Contact method - identifies defects by testing product characteristics.

- Fixed-value - a specific number of movements every time.

- Sequence method - determines if procedure were followed.

Defects found in later operations or steps of a process have more costs associated with them. There are more materials, labor, overhead, previously reworked product that are at risk. Ultimately if the product gets to the customer as a defect, the intangibles, such as reputation, can exceed the tangible cost.

For example, a carbon monoxide detector will not be as effective if the inputs of dangerous and tolerable PPM levels are not known, or if the proper location for installation is not clear.

GOOD: Detect defect before proceeding to next step.

BETTER: Detects defects while in process at an operation.

BEST: Prevent defects from occurring at all.

Each process should have error-proofing to ensure defects are not passed on to the next step and that each operation has mistake proofing in place to ensure only defect free parts are accepted in.

Connection to the FMEA

The FMEA has three categories of:

1) Severity

2) Detection

3) Occurrence

Mistake Proofing is applied to reduce the scores in Detection and Occurrence.

Once a mistake proofing device or method is proven it is important that the GB/BB follow up with the Quality Department to update the company FMEA if applicable.

Severity reduction can also be done as another soft savings benefit from a Six Sigma team.

Reducing all or any of the

three values in these categories will reduce risk (reduce the RPN number of a failure

mode).

The Six Sigma team also updates their own project FMEA and this becomes the Revised FMEA in the CONTROL phase.

Examining the Cost of Defects

There is an initial cost to implementing poka-yokes just like there is a significant cost to implementing SPC. However, this cost will be more than offset in the long-term stability and performance of the output. In other words, if the correct poka-yokes are invested these will help reduce variation and shift the mean (or median) in the desired direction.

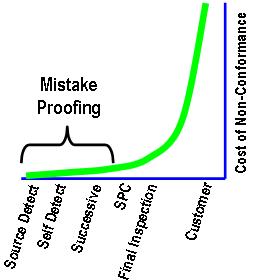

The chart below illustrates the costs to the company at various levels (sources) of DETECTION.

The cost are the most extreme if detected by the customer. Not only directly, but possibly indirectly, if it also affects the ability to win new business.

The further downstream a defects goes undetected the more risk is associated. If a customer finds a defect, there are various Cost of Poor Quality from direct cost to a variety of indirect costs that may not immediately be felt (such as future recalls or lost quoting opportunities).

The Six Sigma team should focus on PREVENTION first. In most cases not 100% defects can be PREVENTED 100% of the time so investments in DETECTION are also necessary.

Examples of Poka-Yoke

The examples listed below are devices that help prevent or detect mistakes. However, there are varying degrees of effectiveness and the team needs to balance getting the most effective poka-yoke while being practical and economical.

Some mistake proofing ideas can add time to the value stream and add costs such as an inspection process or sorting process.

More lead time equals more inventory, longer cash conversion cycle, and contradicts the direction of Lean Manufacturing.

- Spell check on work editor

- UPC codes and scanners (reduces data entry errors)

- Snooze

- Circuit breaker

- Operator training

- Low fuel alarm and visual indicator on vehicle

- Instructions on assembling furniture or light fixture

- Automatic save features on software

- Pull down menus for consistent data entry

- Inspection

- The hole in the upper portion of a sink to prevent overflow

- Pressure relief valve on hot water heater

- Coffee maker shut off feature when pot is removed

- Tinting of contact lenses to assist in locating them

- L or R on the contact lens case to indicate left or right eye

- Kill switch of jet-ski attached to life jacket

- Limit switches

- "Are you sure you want to DELETE?" reminder

- Sorting of suspect material

- Force or sound detection monitors on machines

- Fire and Carbon Monoxide alarms

- Infrared imaging surveys to detect hot spots

- Kill switch on a forklift seat

- Rubble strips on shoulders of roads

- Oven Timer

- Traffic lights

- Rubble strips on road shoulders

- Various lane stripes and colors on roadways

- GFCI outlets

- Double hand jog systems

- Almost any type of sensor or alarm is a poka-yoke device

- Wall stud finder

- Car beeping if the lights are left on

- Automatic shut-off for car lights accidentally left on

More Mistake Proofing examples and photos at www.mistakeproofing.com

It is also important to evaluate if any other problems or risks have been created form the new poka-yoke device. The device should not present a new safety hazard, increase risk of existing failure mode or create a new failure mode.

Example:

Suppose a newly installed shut off valve on the coffee maker functions to prevent spilling below onto the base or countertop when the coffee pot is removed.

This is a very pleasant mistake proofing device, but if the hot water pump doesn't get a feedback signal and continues filling the filter compartment then this could overflow. Essentially, the spill failure mode has been moved from one location to another.

Which of the sinks is lower risk?

The pictures are shown upside down for a reason

The laundry tub is deeper so it could hold more water but the sink in the lower picture has an overflow drain as a source prevention contact control method. This offers more risk aversion than the sink in the top picture. For the sink in the top picture, if the water is accidentally left on with the plug in it (unless it is plugged too!) it will overflow.

Think about stretch ideas that further improve mistake proofing of both? Staying somewhat practical with cost in mind, let your imagination take over.

Other thoughts:

- What if there was sensor that recognized over flow and turned the handles off?

- What if an overflow sounded an alarm or called your phone?

- What if the water amount (and even the temperature) could be programmed quickly at the faucet?

What seemed impractical a few years ago may become practical now or in the future. What value does it add to the customer, maybe the Kano Model could draw out any interest in "delighter" features like this and understand what the customer will pay for them.

More Pictures of Mistake Proofing

Subscribe to access this entire site

Templates, Statistics Tables, and Calculators

Recent Articles

-

Process Capability Indices

Oct 18, 21 09:32 AM

Determing the process capability indices, Pp, Ppk, Cp, Cpk, Cpm -

Six Sigma Calculator, Statistics Tables, and Six Sigma Templates

Sep 14, 21 09:19 AM

Six Sigma Calculators, Statistics Tables, and Six Sigma Templates to make your job easier as a Six Sigma Project Manager -

Six Sigma Templates, Statistics Tables, and Six Sigma Calculators

Aug 16, 21 01:25 PM

Six Sigma Templates, Tables, and Calculators. MTBF, MTTR, A3, EOQ, 5S, 5 WHY, DPMO, FMEA, SIPOC, RTY, DMAIC Contract, OEE, Value Stream Map, Pugh Matrix

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more

Need a Gantt Chart?