Control Plan

Description:

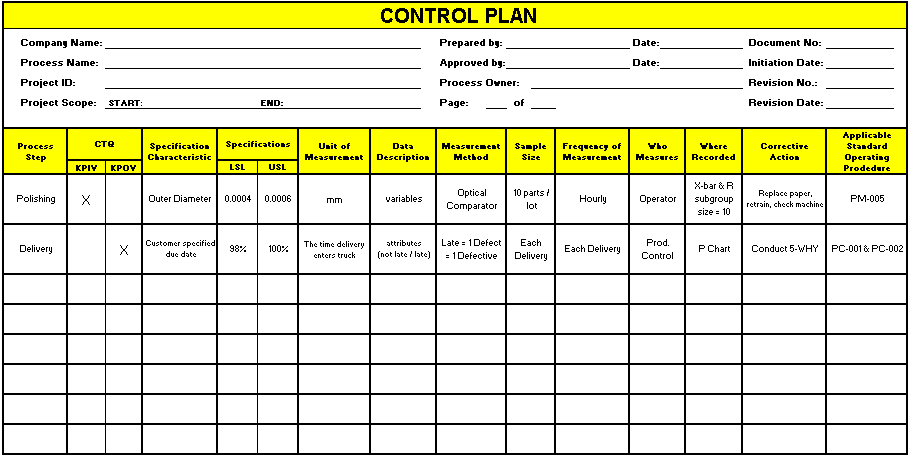

The Control Plan is a guide for the Process Owner to assist in tracking and correcting the performance of the KPIV's and KPOV's.

Objective:

Develop a thorough summary document to clarify the details around controlling the key inputs and key outputs.

Once the project is closed it is not necessarily over.

The Control Plan is one part of ensuring the gains are maintained. If process performance strays out of control there are details and tools to adjust and re-monitor to ensure there has not been an over-adjustment.

It's possible that the new performance capability warrants the calculation of new control limits. If so, the test(s) used, evidence, and new control limits should also be a part of this document. It is ideal to have a simple one-page document but if appendices and attachments are needed to ensure understanding and control then include this information.

A Control Plan's objective is to help ensure that the process remains within control and continues to fulfill customer requirements (VOC).

Creating a Control Plan

A Control Plan is developed by the Six Sigma team. The Six Sigma Project Manager hands the project off to the Champion who monitors the performance over the long term and after the team disbands.

The contents of a Control Plan:

- Measurements: For evaluating the performance of the process, some measurement criteria would have to be decided. The measurement can be of any numerical type like quality score, output, etc.

- Specifications: The measurement would have to be based on limits which can be derived from the specifications provided either by the customer or by any law. Specifications can be provided by the organization itself also.

- Inputs and outputs. The process would require certain things as inputs and will give results as certain output. This will require mentioning what inputs are required to get the desired output, in what quantity and what time duration is needed.

- Major steps involved: The major steps or sub-processes involved which are vital to the functioning of a process should be mentioned along with their success criteria and steps to be taken in case any of the steps fail. Mistake proofing should be done wherever possible to minimize the occurrence of fail scenarios.

- Frequency of monitoring and reporting: A fixed time period should be mentioned to monitor and report the performance of the process and major steps also of the process, if needed.

- Sampling method: An appropriate sampling method as required by the process should be mentioned. Sampling methods can vary for different steps of the process.

- Repository: A repository for storing information should be there for extracting information whenever needed. It will enable the process team to closely monitor the process performance and whenever any special cause occurs, data can be extracted for analysis to understand this special cause. This will also help in the generating reports about process performance at fixed time periods.

- Addressing deviations: Remedial actions are taken for whatever deviations are found. This will help in preventing recurrence of these problems.

- Process Owner, Stakeholders and Persons Responsible: The names of the process owner, persons responsible for various steps of process, their monitoring and reporting and other key activities along with other stakeholders must be mentioned to identify which persons are involved in the process.

After the Project Handoff

The Six Sigma Project Manager (GB/BB) will often move on to another project after the team disbands but follow up is often required weeks or months later. The follow up is done in conjunction with the Process Owner and possibly the Controller.

The GB/BB should take the time to check back in with the Champion to review the process performance and ensure the gains have been sustained or make corrections as needed.

Adhering to the details of the Control Plan will standardize these efforts and allow quick analysis of current performance.

Include all relevant material and information it takes to ensure the gains are sustained.

Often times there are long-term action items and the project list (possibly utilize a Gantt Chart) shall be updated and followed by the Process Owner until those actions are complete.

Control Plan Template

|

This template comes with an example

and is available to purchase (along with other templates and

calculators) by clicking here. |

DMAIC Training Slides - Download

|

These slides include the most common topics found within a Lean Six Sigma program and covers the development of an effective Control Plan. This step can not be underestimated and is the key to SUSTAIN the gains. Click here to purchase the Control Plan module and view others that are available. This set of Training Slides also comes with 180+ practice certification exam questions that come with explanations and links for further research. |

Return to the Six-Sigma-Material Home Page

Recent Articles

-

Process Capability Indices

Oct 18, 21 09:32 AM

Determing the process capability indices, Pp, Ppk, Cp, Cpk, Cpm -

Six Sigma Calculator, Statistics Tables, and Six Sigma Templates

Sep 14, 21 09:19 AM

Six Sigma Calculators, Statistics Tables, and Six Sigma Templates to make your job easier as a Six Sigma Project Manager -

Six Sigma Templates, Statistics Tables, and Six Sigma Calculators

Aug 16, 21 01:25 PM

Six Sigma Templates, Tables, and Calculators. MTBF, MTTR, A3, EOQ, 5S, 5 WHY, DPMO, FMEA, SIPOC, RTY, DMAIC Contract, OEE, Value Stream Map, Pugh Matrix

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more

Need a Gantt Chart?