Box-Cox Transformation

The Box-Cox Transformation is one method of transforming non-normal data, or data that cannot be assumed normal, to meet a normal distribution and allow further capability analysis and hypothesis testing.

The term is named after statisticians George and David Cox which is a method that uses an exponent, Lambda, to transform the data.

The value of Lambda is the power to which each data point is raised Xl

Then a new (transformed) set of data is created and that transformed set of data is used in for statistical analysis.

The tool is typically used in the ANALYZE phase of a DMAIC project.

Data Assumptions for using Box-Cox:

- Continuous X and Y

- Data does not contain negative numbers or zero

- The order of data must remain the same after the transform is complete

- Data being transformed must be smooth and continuous (multimodal or bimodal data can not be transformed using this technique)

- Maximum observation in original data must be at least twice as large as the minimum such as 5 to 10.

- The specifications (such as LSL and USL) must also be transformed if a capability analysis is being performed and be >0.

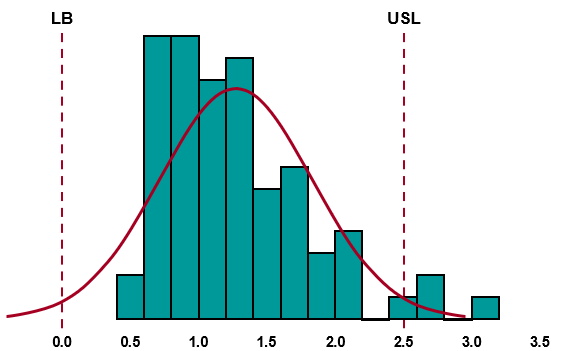

When the data is not normally distributed, this could result in inaccuracies when calculating a z-score. This could result in an inaccurate representation of your process capability.

Control charts may depict a process that is more or less in control than in reality; and, when performing a hypothesis tests the results of your tests may not be accurate, especially as the data is less normal.

NOTE

A Box-Cox transformation for ln (l = 0) requires that the LSL, USL and data are >0. You may find that your lower specification limit (LSL) is originally < or = 0. If your LSL is zero, this requires a offset to each the LSL, the data, and USL.

Often the LSL may not be specified but it is known to be a Lower Bound (LB). Such as if you are evaluating pieces per hour and Parts Per Million (PPM). It is not possible to have <0 but a LB of exactly 0 does exist.

For example:

If you have a LSL of 0.0 and an USL of 5.0, you can add 0.1 to the LSL to make it 0.1 and the USL becomes 5.1. You must also add 0.1 to all the original data points.

Then run the Box-Cox transformation (after you verify the transformed data is normal, should get a p-value > 0 on the transformed data) and get your PPM.

The data analyzed below has a P-value of 0 and thus is non-normal. You can the see the LSL (or LB) is = 0. When running a Box-Cox transformation for ln (l = 0), add an offset such as 0.01 or 0.1 to all the data points, LB, and USL and run the transformation.

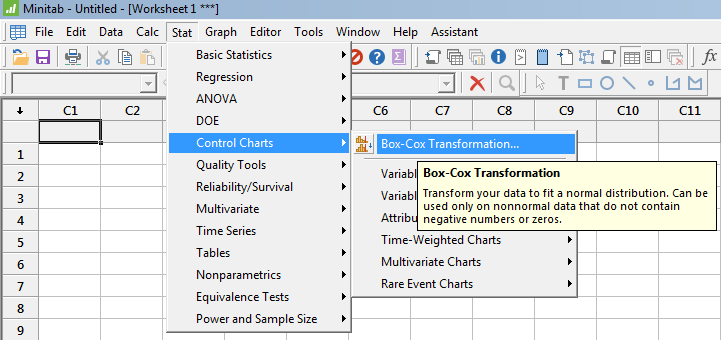

Box-Cox Transformation using Minitab

The menus may change depending on the version of Minitab being used. However, the concept and general flow of the process will be similar. Use the 'Help' menu to advise on how to conduct this transformation using your version.

Site Membership

LEARN MORE

Six Sigma

Templates, Tables & Calculators

Six Sigma Slides

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Process Mapping

Capability Studies

MSA

SIPOC

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

T Tests

1-Way ANOVA

Chi-Square

Correlation

Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Z Scores

OEE

Takt Time

Line Balancing

Yield Metrics

Sampling Methods

Data Classification

Practice Exam

... and more

Need a Gantt Chart?