Line Balancing

Description

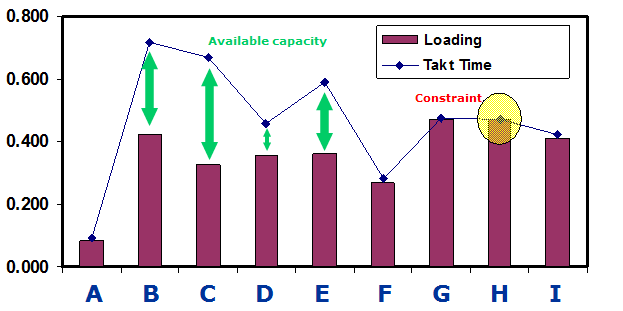

Line Balancing is leveling the workload across all processes in a cell or value stream to remove bottlenecks and excess capacity. A constraint slows the process down and results if waiting for downstream operations and excess capacity results in waiting and no absorption of fixed costs.

Objective

Match the production rate after all wastes have been removed to the Takt time at each process of the value stream.

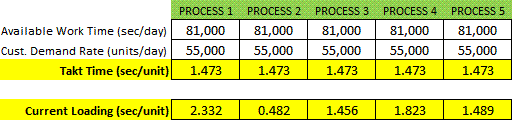

EXAMPLE:

Taking the example from the Takt time page as the starting point, there were additional studies conducted each the remaining processes that it takes to make UNIT ABC.

Often the bottlenecks or areas of excess capacity are known by the team members but this analysis provides the quantitative data to prioritize activities to improve.

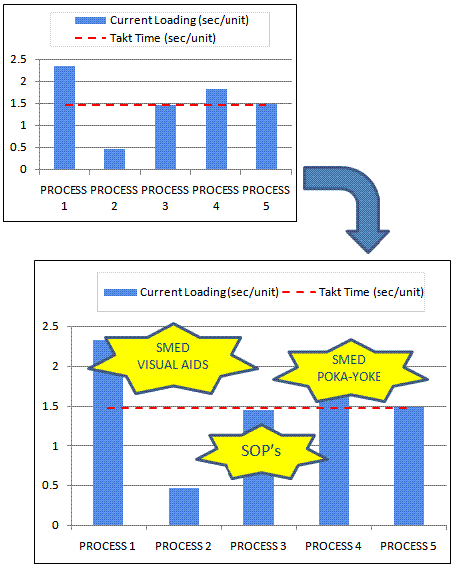

Process 1: Taking much longer than Takt time. Overtime is probably used to make up production and is the #1 constraint.

Process 2: Exceeding the Takt time, probably a lot of waiting and the excess capacity can be filled by absorbing some of the work from Process 1 and/or Process 4.

Process 3 & 5: Very close to meeting Takt time, not a focus area but possibly some best practices and application of LEAN tools can improve these loading rates. Improvement in these areas could be used to share workload from constraint processes.

Process 4: Taking longer than Takt time. Again, overtime is probably used or there are late deliveries, high expediting costs or unhappy customers. Apply Lean Manufacturing principles and try to alleviate workload to Process 2 or others that may be able be improved to absorb some of the workload.

Examine all the specific activities occurring in each process. Time studies, motion studies, and other Lean tools often provide most the ideas for improvement.

Develop a plan for immediate, low-cost improvements. Professional signage, advanced comprehensive training and capital investments are not needed or justified yet.

Run studies to determine the potential LOADING improvements. There is most likely not much that can be done to change the Takt time; focus on improving the LOADING (production rate).

Improving the LOADING, even in non-constraint operations is desirable, but the top priority is relieving constraint operations.

AFTER

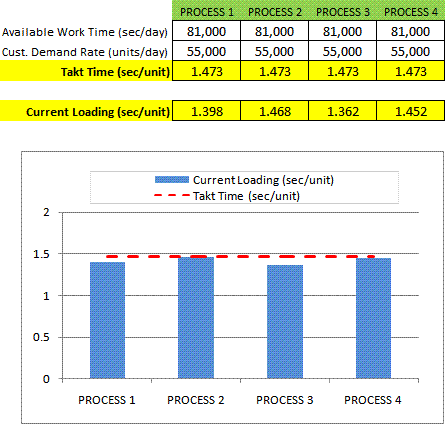

The table and chart below shows the results of the Line Balancing improvements.

There were gains...and the success was to the point where there was excess capacity. All the activities could now be completed in four processes. Floor space was gained and excess older and fully depreciated equipment were sold for cash.

A new loading study was done and the results are shown.

Recall, the goal of Line Balancing is to have the loading rates meet the Takt time and this is accomplished as the chart indicates.

Takt Time and Line Balancing Calculator

|

A Takt Time and Loading calculator with an example is available here. Within the file are explanations to assist with completing the template. |

Templates, Tables, and Calculators

Site Membership

Click for a Password

to access entire site

Six Sigma

Templates & Calculators

Six Sigma Modules

The following are available

Click Here

Green Belt Program (1,000+ Slides)

Basic Statistics

Cost of Quality

SPC

Process Mapping

Capability Studies

MSA

Cause & Effect Matrix

FMEA

Multivariate Analysis

Central Limit Theorem

Confidence Intervals

Hypothesis Testing

T Tests

1-Way ANOVA

Chi-Square

Correlation and Regression

Control Plan

Kaizen

MTBF and MTTR

Project Pitfalls

Error Proofing

Effective Meetings

OEE

Takt Time

Line Balancing

Practice Exam

... and more